- Insulation

- Thermal envelope

Thermal envelope

Thermal envelope of the house

At Marles, we understand that a well-insulated house with a properly designed and precisely executed thermal envelope means significant energy savings not only in winter, when the house needs to be heated, but also in summer, when a properly designed and precisely executed thermal envelope can contribute to optimum living conditions and a pleasant indoor environment.

Thanks to a thoughtful construction method and meticulous detailing in production and assembly, the insulation layer is never broken. Breakthroughs are kept to a minimum and low thermal conductivity materials (cellulose, DP5 grade rock mineral wool and Neopor®) are used for insulation to ensure the highest possible quality.

Blower door test

To ensure the airtightness of the building, we carry out a Blower Door Test, which measures the amount of uncontrolled air passage from the building. Airtightness prevents the uncontrolled passage of outside air, which is essential for a good thermal envelope.

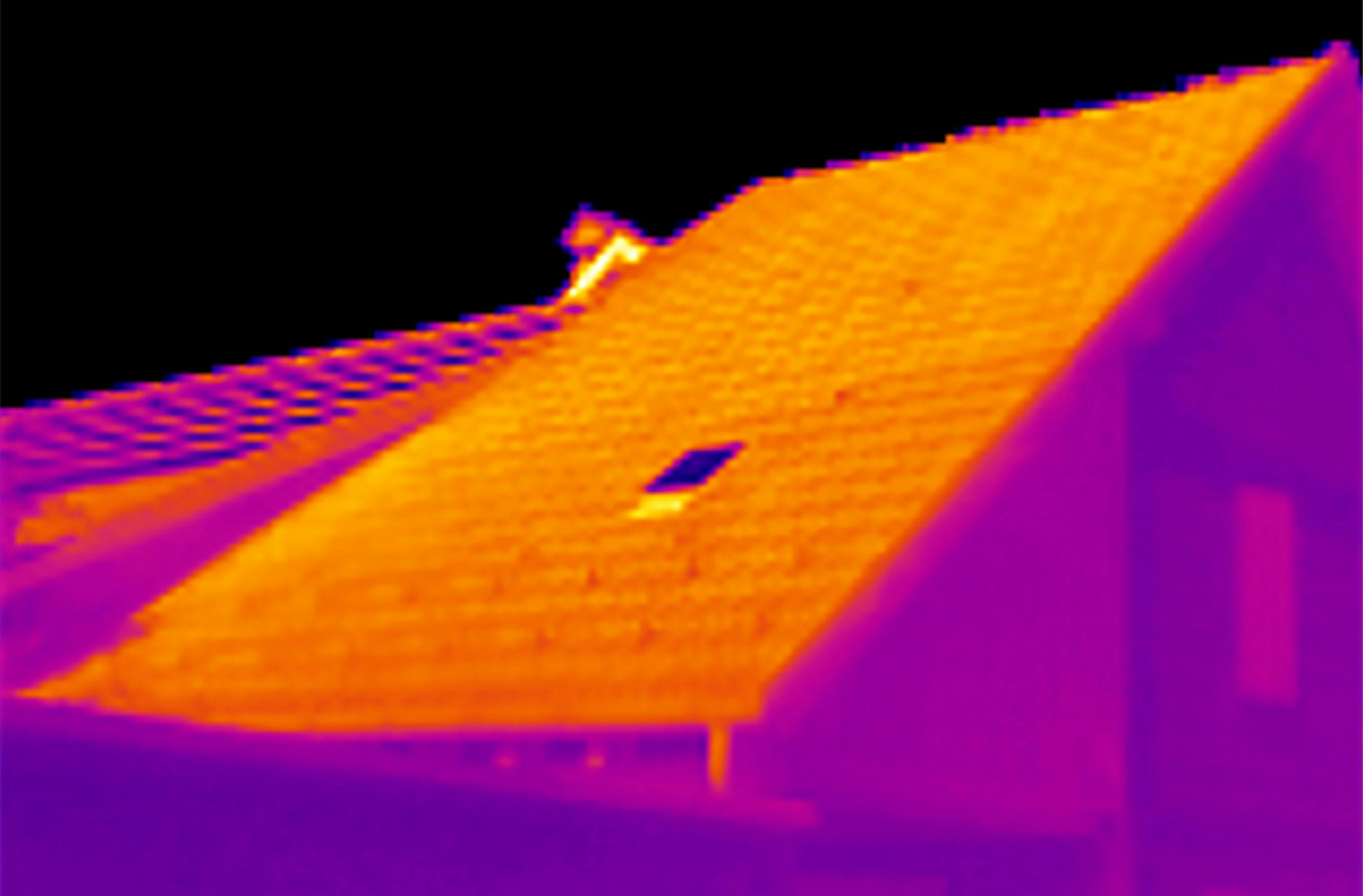

Thermography

To detect potential thermal bridges, we use a thermographic camera that measures the surface temperature of the building elements. Through intelligent construction from the design stage and the use of materials with low thermal conductivity, we ensure minimal heat loss. Thermographic images of complex Marles buildings show an exceptional thermal envelope, which is further confirmed by inspection with a thermographic camera.